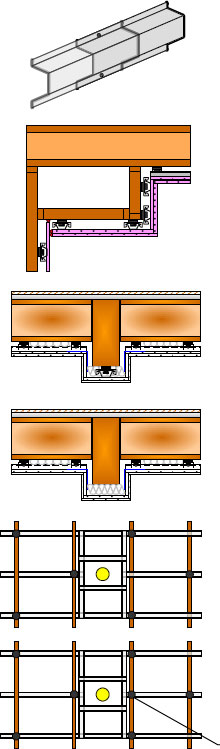

Splice drywall furring channel (hat track) with 6 inch overlap in mid span (between two clips) secure with 18 ga tie wire, or two 7/16" framing screws

Labor rates provided to PAC International, Inc by an independent contracting firm.

Approved for use in over 150 different UL fire resistive design assemblies.

Check our website for the latest updates of the fire testing approvals

WWW.PAC-INTL.COM

Check UL Fire Resistance Directory File # R16638

Check UL's web pages. www.ul.com/database

Contact UL (877) UL- HELPS

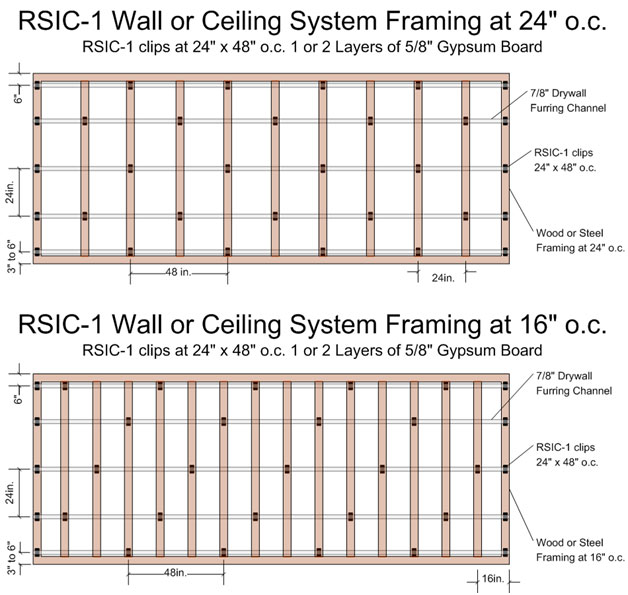

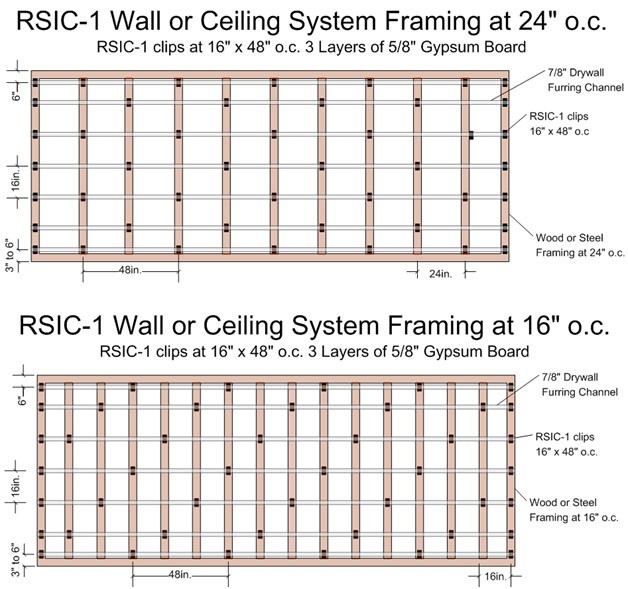

INSTALLING RESILIENT SOUND ISOLATION CLIPS (RSIC-1)

INSTALLING RESILIENT SOUND ISOLATION CLIPS (RSIC-1)

Drywall Furring Channel Overlap:

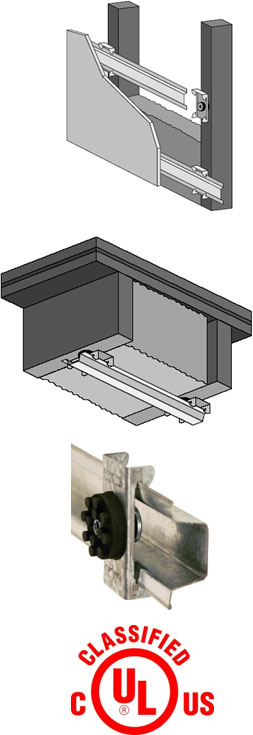

RSIC clip Soffit installation:

RSIC clip Beam installation:

RSIC clip Transition or interruption installation:

Optional RSIC-1 clip added to support the end of the channel

CIKV.R16638

Types RSIC-1 and RSIC-1 (2.75) for use in Design Nos. G501, G502, G503, G504, G505, G507, G510, G512, G524, G525, G534, G551, G552, G561, G565, G578, G552, G565, L502, L505, L510, L511, L513, L514, L516, L518, L521, L523, L528, L532, L534, L542, L546, L547, L550, L562, L563, L569, L570, L573, L574, L576, L579, L582, L587, L589, L590, L593, M501, M502, M506, M508, M509, M510, M514, M531, P519, P522, P538, P545, P556, P571, U301, U305, U309, U311, U320, U331, U334, U340, U341, U342, U344, U356, U411, U415, U417, U419, U421, U423, U440, U451, U453, U455, U465, U473, U493, U524, U910, U914, V310, V323, V324, V438, V455, V469, V478, V481, V488, V489, V490, V496, V498, W419, W425, W440, W445.

Type RSIC-1 also Classified in accordance with ASTM E90-99, "Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements". See Design Nos. G505, U305, U334, V310, for STC rating.

Type RSIC-1 also Classified in accordance with ASTM E492-96, "Standard Test Method for Laboratory Measurement of Impact Sound Transmission Through Floor-Ceiling Assemblies Using the Tapping Machine". See Design No. G505 for IIC rating.

Types RSIC-1 and/or RSIC-1 (2.75) for use in Joint System Nos. HW-D-0060, HW-D-1011.

WARRANTY DISCLAIMER AND LIABILITY LIMITATION LANGUAGE

NO EXPRESS OR IMPLIED WARRANTIES

THERE IS NO WARRANTY, REPRESENTATION OR CONDITION OF ANY KIND; AND ANY WARRANTY, EXPRESS OR IMPLIED, IS EXCLUDED AND DISCLAIMED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow limitations on implied warranties, so the above limitation may not apply to you.

LIABILITY LIMITED TO RETURN OF PURCHASE PRICE

IT IS AGREED THAT SELLER'S LIABILITY AND PURCHASER'S SOLE REMEDY, WHETHER IN CONTRACT, UNDER ANY WARRANTY, IN TORT (INCLUDING NEGLIGENCE), IN STRICT LIABILITY OR OTHERWISE, SHALL NOT EXCEED THE RETURN OF THE AMOUNT OF THE PURCHASE PRICE PAID BY PURCHASER, AND UNDER NO CIRCUMSTANCES SHALL SELLER BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO, PERSONAL INJURY, PROPERTY DAMAGE, DAMAGE TO OR LOSS OF EQUIPMENT, LOST PROFITS OR REVENUE, COSTS OF RENTING REPLACEMENTS AND OTHER ADDITIONAL EXPENSES, EVEN IF SELLER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. THE PRICE STATED FOR THE EQUIPMENT IS A CONSIDERATION IN LIMITING SELLER'S LIABILITY AND PURCHASER'S REMEDY. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

SELLER NOT LIABLE FOR PURCHASER'S NEGLIGENCE

SELLER WILL NOT BE LIABLE FOR ANY DAMAGES, LOSSES OR EXPENSES AS A RESULT OF PURCHASER'S NEGLIGENCE, WHETHER DEEMED ACTIVE OR PASSIVE AND WHETHER OR NOT ANY SUCH NEGLIGENCE IS THE SOLE CAUSE OF ANY SUCH DAMAGE, LOSS OR EXPENSE.

MODEL FOR DEMONSTRATION PURPOSES ONLY

THE MODEL OR SAMPLE SHOWN BY SELLER TO BUYER IS USED FOR DEMONSTRATION PURPOSES ONLY. THERE IS NO WARRANTY THAT THE GOODS AS DELIVERED SHALL CONFORM TO THE MODEL OR SAMPLE, AND CONFORMITY OF THE GOODS TO THE MODEL OR SAMPLE IS NOT PART OF THE BASIS OF THE BARGAIN BETWEEN SELLER AND BUYER.

NOWARRANTY OR COMPLIANCEWITH SAFETY CODE OR REGULATION

SELLER DOES NOT WARRANT THAT ANY OF THE GOODS SOLD WILL MEET OR COMPLY WITH THE REQUIREMENTS OF ANY SAFETY CODE, BUILDING OR DWELLING CODE, OR REGULATION OF ANY STATE, MUNICIPALITY OR OTHER JURISDICTION.

NEVADA LAW APPLIES

SELLER AND BUYER AGREE THAT ALL ASPECTS OF THIS TRANSACTION INCLUDING THE APPLICABLE STATUTE OF LIMITATIONS SHALL BE GOVERNED BY THE INTERNAL LAW OF THE STATE OR NEVADA, AND NOT THE LAWS OF CONFLICTS. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.